Heavy Duty Drive in Pallet Racks Wholesale

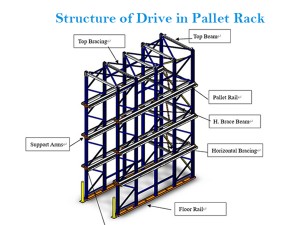

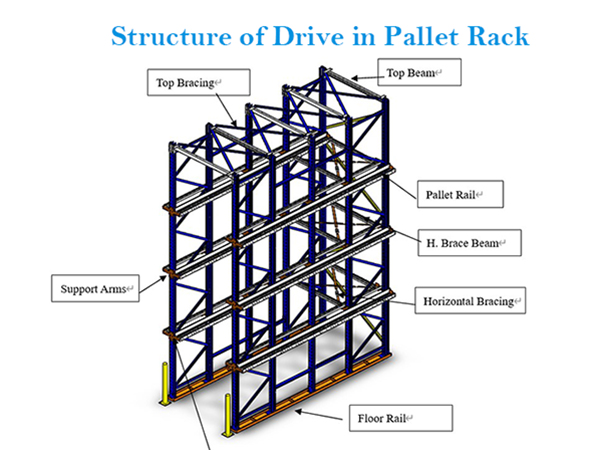

Drive-In Racking is a high-density storage system that eliminates the traditional individual aisles between shelves and instead creates continuous storage units. Forklifts can drive directly into the racks for storage and retrieval, achieving an "aisle-as-location" space utilization model. Its core design concept sacrifices some storage and retrieval efficiency in exchange for significantly increased storage density, making it particularly suitable for bulk goods, seasonal products, and cold chain storage.

Features of Drive-In Racking

Continuous Pallet Storage

Racks can be designed with multiple pallet positions (typically 3-10 pallets deep) in depth, forming continuous storage aisles.

Direct Forklift Access

Equipped with dedicated guide rails and protective components, drive-in racks allow forklifts to access deep storage and retrieval of goods.

FILO (First-In-Last-Out) Management

Goods are stored and retrieved from the same aisle and end, making it suitable for managing large batches of goods with a limited variety.

Customized Structural Design

Column specifications, guide rail inclination, and reinforcement solutions are customized based on warehouse clearance, load requirements, and forklift specifications.

Advantages of Drive-In Racking

Space Utilization Increased by Over 60%

By consolidating operating aisles, the effective storage area is increased from 40% of conventional racking to over 75%.

Reduced Cost Per Pallet by 30%

The increased storage density significantly reduces the overall storage cost per pallet (including site rental, equipment depreciation, etc.).

Load Capacity of 2000kg/Location

Reinforced columns (e.g., 90×70×2.0mm) and a double-beam structure support multi-layer stacking of heavy goods.

Compatible with Automation Upgrades

Can be combined with a shuttle system for semi-automated operation, further reducing labor costs and operational errors.

Applications of Drive-In Racking

Food and Beverage Industry

Bulk storage of seasonal fast-moving consumer goods such as beer and beverages to meet stocking needs during peak sales seasons.

Cold Chain Logistics Center

Maximize the utilization of expensive, low-temperature space to store frozen foods, medical supplies, and other temperature-controlled goods.

Manufacturing Raw Materials Warehouse

Buffer inventory management for bulk production materials such as plastic pellets and paper rolls.

Third-Party Logistics Warehousing

Provides high-density storage solutions for e-commerce bulk goods and home appliances.

Get your customized plan now

We provide a free site survey and 3D warehouse layout design to deliver the most cost-effective drive-in racking solution based on your product SKUs, traffic data, and equipment specifications.

Service Hotline/Whatsapp: 86-152-5923-3328

Submit your requirements online: https://www.spiethstorage.com/contact-us/