Discountable price Radio Shuttle Cart Manufacturer From China

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Discountable price Radio Shuttle Cart Manufacturer From China, Accurate process devices, Advanced Injection Molding Equipment, Equipment assembly line, labs and software development are our distinguishing feature.

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for China Radio Shuttle Cart, Radio Shuttle Cart System, The company attaches great importance to product quality and service quality, based on the business philosophy “good with people, genuine to whole world, your satisfaction is our pursuit”. we design goods, According to customer’s sample and requirements, to meet the needs of the market and give different customers with personalised service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

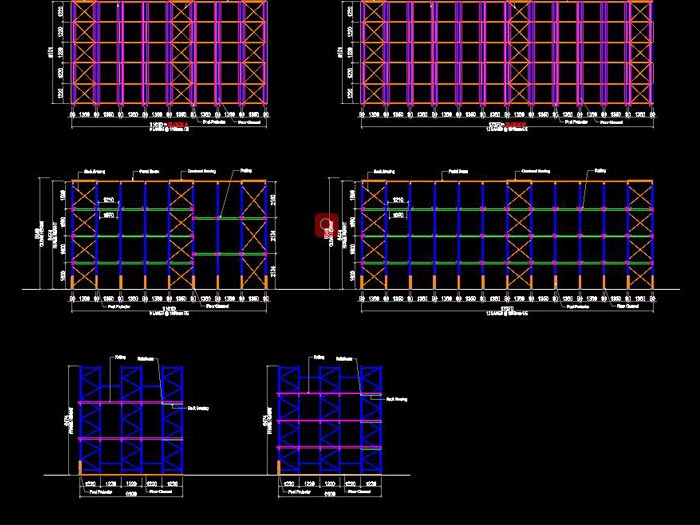

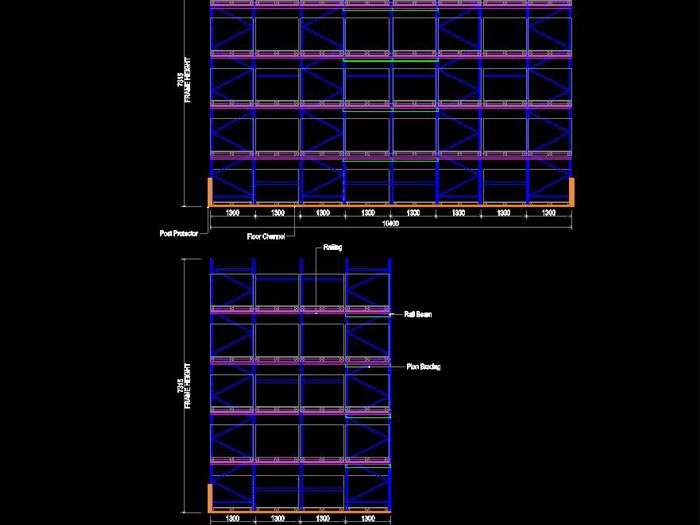

Drive-in and drive-through pallet rack are storage rack configurations that allow the forklift to drive directly into the lane of stacked rows. Drive-in Pallet Racking produces efficiencies through decreasing section launching as well as unloading occasions, however permitting higher entry when compared with block-stacking. Placement pallets upon front-to-back bed rails enables series to become piled following to one another properly as well as effectively

This particular racking system is actually the most suitable with regard to producers associated with items which are manufactured in order, or even within warehouse procedure exactly where you will find restricted items SKU as well as pallets can’t be properly obstructed or even piled. Commonly used within cold room storage that need optimum utilization of room for that storage space associated with items inside a managed heat.

|

Model |

First-in Last-out Drive in Racking System Drive Through Pallet Racking |

|

Main Parts |

Frame, beam, Connect Arm, Support rail, Bracer and Post Protector |

|

Load Capacity |

1000kg/pallet |

|

Surface Treatment |

Powder Coating |

|

Advantage |

1. LIFO(last in first out) /FIFO(first in first out) configurations; 3. Designed around the combination of your pallets and forklifts |

|

Color |

Blue/Orange or as your requirement |

|

Delivry Time |

within 15 days for the ordinary quantity; Big qty will make a special arrangement as your schedule |

Drive in racking Drawing